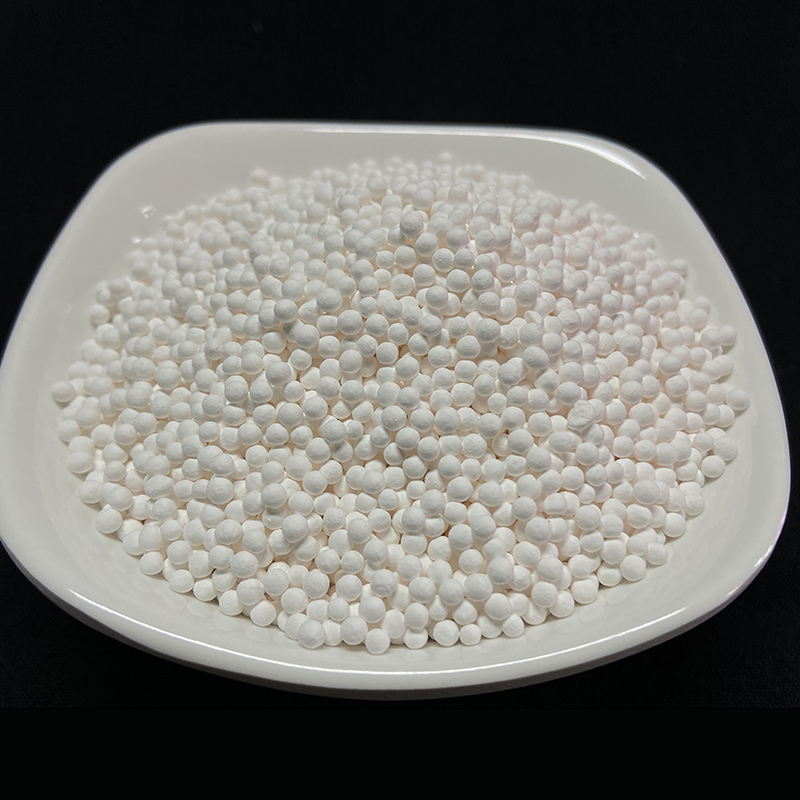

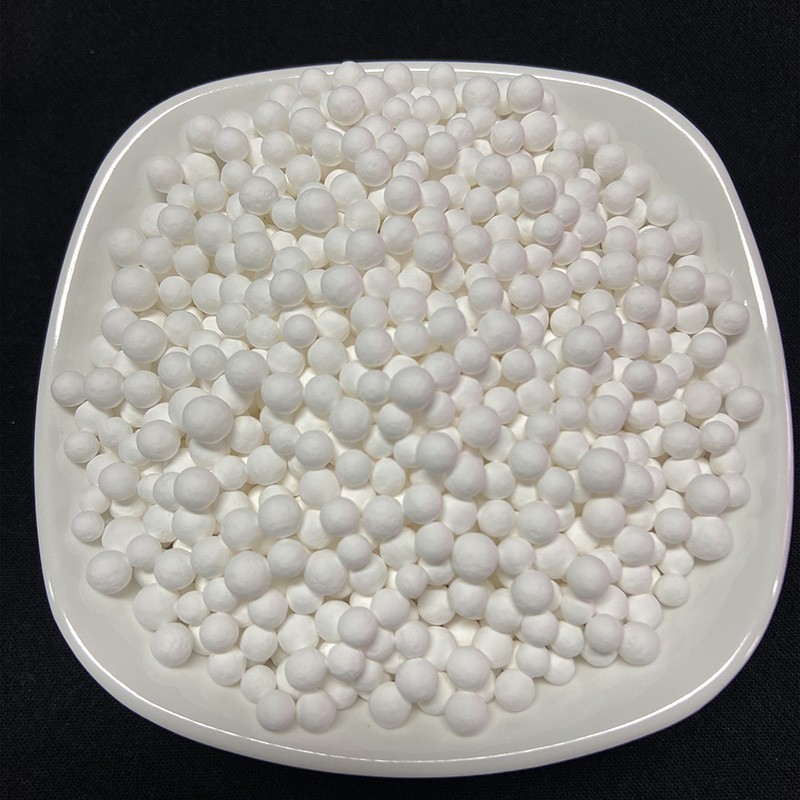

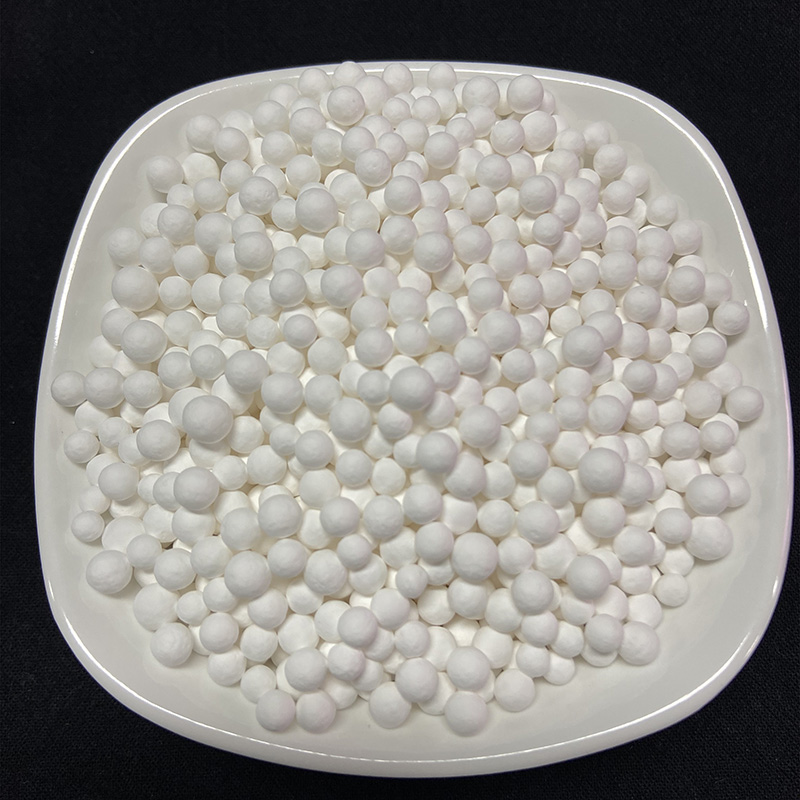

I-Alumina Ceramic Filler High Alumina Inert Ball / 99% ye-alumina ye-ceramic ibhola

IiPropati zeMzimba kunye nezeMichiza yeeBhola zeCeramic ezingasebenziyo

| Iimpawu ezibonakalayo kunye neekhemikhali zeebhola ze-ceramic ze-inert | |||||||

| Isiqalelo | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Amacandelo aseleyo anokuqinisekiswa ngothethwano phakathi komthengisi kunye nomthengi xa kuyimfuneko. | |||||||

| ukufunxwa kwamanzi,% | 3±1,Inokumiselwa ngothethwano phakathi komthengisi kunye nomthengi | ||||||

| umlinganiselo, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Ukuxinana ngobuninzi,kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Uthuli, ukuqhekeka okanye ukwaphuka | Ibhegi enye ingaphantsi kwe 5% | ||||||

| Ubungakanani bokutenxa | I-uniform sphere, umlinganiselo weyona dayamitha inkulu ukuya kwencinci ye-ceramic sphere ayidluli kwi-1.2 | ||||||

| Ukunyamezela komgangatho | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26-50mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Amandla okuwa kwamahhala | Ixabiso elingenakulahlekelwa ≥99% | ||||||

| Amandla acinezelayo | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Ixabiso lokunxiba % | ≤2 | ≤1 | |||||

| ukunyibilika kweasidi,% | ≤6 | ||||||

| Ialkalinity,% | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Ukuchasa, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Ukumelana nokwahlukana koxinzelelo ngesiquphe | Izinga elingonakalisi ≥ 99%, akukho tshintsho kumandla oxinzelelo kunye noxinzelelo emva kokutshintsha ngokukhawuleza kungaphantsi kwe-25% | ||||||

| Ukumelana nokutshintsha kobushushu ngesiquphe | Ixabiso elingenakulahlekelwa≥99% | ||||||

| Iphakheji | Ukupakishwa kwegubu lentsimbi | Ipakishwe kwimigqomo yentsimbi, itywinwe ngePP eshinyeneyo okanye iingxowa zeplastiki zePE | |||||

| Ukupakishwa kwengxowa ephothiweyo | Ifumaneka kwiingxowa ezilukiweyo ezomeleleyo kunye ne-UV-resistant | ||||||

| Qaphela: Idatha yobuninzi bobuninzi yenzelwe ireferensi kuphela, kungekhona njengesiseko sokwamkelwa. | |||||||

Elinye inqaku: Jonga iTheyibhile yesi-5 yokufunxwa kwamanzi kwiiBhola zokuzalisa ezingama-99

| 99 Ukuzalisa ukufunxwa kwaManzi eBhola | ||

| 99 isihluzi | ububanzi | ububanzi |

| ukwenza umqulu | φ<25mm | <5% |

| Ukwenziwa komatshini wokushicilela | φ>25mm | <10% |

99.5% iZalathi zobuGcisa

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| CaO +MgO | ≤0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Isalathiso sePhysical Filler Ball

| IMEKO | INDEX |

| ukuthambisa umthwalo (yb/t370-1995) | Ukuguqulwa phantsi koxinzelelo lwe-0.2mpa lungaphantsi kwe-0.6% |

| Ukuxhathisa ukothuka kweThermal (yb/t376.2-1995) | 1200°C ukuhla ukuya kuma-600°C. Amaxesha e-10 ngaphandle kokuqhekeka komhlaba |

| Ukutshintsha kwakhona umgca wokutshintsha (gb/t3997.1-1998) | I-1400 ℃ kwiiyure ze-12, ixabiso eliphezulu li-0.25%, ixabiso eliqhelekileyo lingaphantsi kwe-0.20% |

| Ubuninzi bobuninzi (gb/t2997-2000) | 3.2-3.50 g / cm3 |

| amandla okutyumza | Hlangana ngaphezu kwe-230 kg / cm2 |

| I-porosity ebonakalayo | 12-18% |

| Unizi lolwapho kuyiwa khona | 2.1-2.3g/cm3 |

Imichiza yokuPakisha ibhola yokupakisha

1) Ukupakisha okuqhelekileyo: isikhwama esilukiweyo se-polyethylene esinobunzima obungama-25kg, kunye nephalethi

2) Ukupakishwa kwedrum yentsimbi: I-100L yokupakisha idramu yentsimbi, iipallets zingongezwa