IZIQULATHO

-

I-AGO-0X5L Catalyst ye-PA Production evela kwi-0-xylene

Ukuma kweMichiza

I-V-Tl i-oxide yentsimbi egqunywe kwi-inert carrier

Iipropati Zomzimba

Ubume beCatalyst

Umsesane ongenanto rhoqo

Ubungakanani beCatalyst

7.0*7.0*3.7±0.1mm

Unizi lolwapho kuyiwa khona

1.07±0.5kg/L

Inani leLeya

5

Iiparamitha zokuSebenza

Imveliso ye-Oxidation

113-115wt% emva konyaka wokuqala

112-114wt% emva konyaka wesibini

110-112wt% emva konyaka wesithathu

Ubushushu bendawo eshushu

400-440℃(Eqhelekileyo)

Ukwehla koxinzelelo lwe-Catalyst

0.20-0.25 Ibha (G)

Ubomi beCatalyst

> iminyaka emi-3

Imeko yokusetyenziswa kweZityalo zoRhwebo

Ukuhamba komoya

4. 0NCM/ityhubhu/h

Umthwalo we-O-xylene

320g/ityhubhu/h (Eqhelekileyo)

400g/ityhubhu/h(Ubukhulu)

I-0-xylene yoxinaniso

80g/NCM (Eqhelekileyo)

100g/NCM (Ubukhulu)

Ubushushu beTyuwa

350-375℃

(Ngokwemeko yesityalo somthengi)

Iimpawu zeMveliso kunye neeNkonzo I-AGO-0X5L, inani le-catalyst layers yi-5 layers, ephuhliswayo kwaye iphuculwe ngokusekelwe kwi-phthalic ephuculweyo yeteknoloji ye-hydride catalyst eYurophu. Olu hlobo lwe-catalyst luneempawu zomsebenzi ophezulu kunye nesivuno esiphezulu, kwaye umgangatho wemveliso uzinzile kwaye unokwethenjelwa. Okwangoku, uphando lwe-catalyst kunye nophuhliso kunye nokuveliswa kovavanyo luye lwagqitywa, kwaye imveliso ye-industria iya kwenziwa kungekudala.

Ukubonelela ngokulayishwa kwe-catalyst kunye nokuqaliswa kweenkonzo zobugcisa.

Imbali yeMveliso 2013—————————————–R&D iqalile kwaye iyaphumelela

Ekuqaleni kuka-2023—————-R&D iphinde yaqalwa, uqinisekiso lugqityiwe

Phakathi 2023———————–Industrial trial production

Ekupheleni kuka-2023——————————Silungele ukuziswa

-

I-AOG-MAC01 ibhedi esisigxina yebenzene Oxidation ukuya kwi-Maleic Anhydride catalyst

I-AOG-MAC01ibhedi esisigxina benzene Oxidation ukuya Maleic Anhydride catalyst

Ingcaciso yeMveliso:

I-AOG-MAC01Fixed-bed benzene Oxidation ukuya Maleic Anhydride catalyst ukuthatha

I-oxide exutyiweyo kwi-inert carrier, i-V2O5 kunye ne-MoO3 njengamacandelo asebenzayo, iyasetyenziswa

Kwibhedi esisigxina yebenzene oxidation kwi-maleic anhydride. I-catalyst ine-

Iimpawu zomsebenzi ophezulu, ukuqina okuphezulu, i-98% -99% izinga lokuguqulwa, okulungileyo

ukukhetha kunye ne-90% -95% isivuno. I-catalyst iphathwe ngokusebenza kwangaphambili

kunye nokusetyenzwa kobomi obude, ixesha lokuqala lokungeniswa liyancipha kakhulu,

Ubomi benkonzo yemveliso bufikelela kwiminyaka emibini okanye ngaphezulu.

Iimpawu zomzimba kunye neekhemikhali:izinto

isalathisi

Imbonakalo

Umbala omnyama-blue

Ukuxinana ngobuninzi,g/ml

0.75-0.81g/ml

Iinkcukacha zokwakheka, mm

Umngxunya oqhelekileyo 7 * 4 * 4

Indawo engaphezulu, ㎡/g

>0.1

Ukwakhiwa kweekhemikhali

V2O5, MoO3 kunye nezongezo

Amandla okutyumza

I-Axial10kg/inxalenye, i-radial5kg/inxalenye

Iimeko zokusebenza ezibhekiselele:

Ubushushu,℃

Inqanaba lokuqala 430-460 ℃, eqhelekileyo400-430 ℃

Isantya sesithuba, h -1

2000-2500

Ugxininiso lweBenzene

42g-48g /m³isiphumo esihle, 52g//m³ ingasetyenziswa

Inqanaba lomsebenzi

Izinga lokuguqulwa kweBenzene 98% -99%

1. Ukusebenzisa i-oyile-benzene yeyona nto ingcono kwi-catalyst, kuba i-thiophene kunye ne-sulphur iyonke kwi-benzene iya kunciphisa umsebenzi we-catalyst wokusebenza, emva kokuba isixhobo sisebenza ngokuqhelekileyo, i-coking ephezulu ye-benzene ingasetyenziswa.

2. Kwinkqubo, iqondo lokushisa kwindawo eshushu akufanele lidlule i-460 ℃.

3. Isantya sesithuba se-catalyst phakathi kwe-2000-2500 h -1 sinesiphumo esihle kakhulu. Kakade ke, ukuba isantya sendawo sikhulu kunolu, sikwasebenza kakuhle, kuba sisimsithezi esinesantya esiphezulu sendawo.

Ipakethe kunye nothutho:

Ngexesha lokugcinwa kunye nenkqubo yokuthutha, i-catalyst ibubungqina obupheleleyo bokufuma, ayinamanzi kwaye akufanele idlule kwiinyanga ezi-3 xa ibekwe emoyeni. Singakwazi ukupakisha ngokuguquguqukayo ngokweemfuno zabathengi. -

I-Gamma yasebenza i-alumina/i-Gamma Alumina Catalyst Abathwali/i-gamma alumina bead

Into

Iyunithi

Isiphumo

Isigaba seAlumina

Gamma Alumina

Ukuhanjiswa kobungakanani beNcam

D50

μm

88.71

<20μm

%

0.64

<40μm

%

9.14

>150μm

%

15.82

Ukuqulunqwa kwemichiza

Al2O3

%

99.0

SiO2

%

0.014

Na2O

%

0.007

Fe2O3

%

0.011

Intsebenzo yoMzimba

BET

m²/g

196.04

Umthamo wePore

Ml/g

0.388

Ubungakanani bomndilili wePore

nm

7.92

Unizi lolwapho kuyiwa khona

g/ml

0.688

I-Alumina ifunyenwe ukuba ikhona ubuncinane i-8 yefom, ziyi-α- Al2O3, θ-Al2O3, γ- Al2O3, δ- Al2O3, η- Al2O3, χ- Al2O3, κ- Al2O3 kunye ne-ρ- Al2O3, iipropati zabo ze-macroscopic ezihlukeneyo nazo zahlukile. I-alumina esebenzayo yeGamma yikhyubhiki evaliweyo epakishwe ngekristale, enganyibilikiyo emanzini, kodwa inyibilika kwiasidi kunye nealkali. I-alumina esebenzayo ye-gamma ibuthathaka kwinkxaso ye-asidi, inendawo ephezulu yokunyibilika eyi-2050 ℃, ijeli ye-alumina ekwimo ye-hydrate inokwenziwa kwi-oxide ene-porosity ephezulu kunye nomphezulu othile ophakamileyo, inezigaba zotshintsho kuluhlu olubanzi lobushushu. Kwiqondo lokushisa eliphezulu, ngenxa yokuphelelwa ngamanzi emzimbeni kunye ne-dehydroxylation, i-Al2O3surface ibonakala ilungelelanisa i-oksijini engaxutywanga (iziko le-alkali) kunye ne-aluminium (iziko le-asidi), kunye nomsebenzi we-catalytic. Ke ngoko, i-alumina ingasetyenziselwa njengomphathi, i-catalyst kunye ne-cocatalyst.I-alumina esebenzayo yeGamma inokuba ngumgubo, iigranules, imicu okanye ezinye. Sinokwenza ngokwemfuno yakho.γ-Al2O3, yayibizwa ngokuba “i-alumina esebenzayo”, luhlobo lwezixhobo eziqinileyo ezisasazekileyo, ngenxa yesakhiwo sayo esilungelelanisiweyo sepore, indawo enkulu ethile yomphezulu, ukusebenza kakuhle kwe-adsorption, umphezulu onezibonelelo zeasidi kunye nokuzinza okuhle kwe-thermal, umphezulu we-microporous kunye neepropati ezifunekayo ze-catalytic action, ngoko ke i-catalyst ye-catalyst isetyenziswa kakhulu umthwali kwimveliso yeekhemikhali kunye ne-oyile, kwaye idlala indima ebalulekileyo kwi-oil hydrocracking, i-hydrogenation refining, i-hydrogenation reforming, i-dehydrogenation reaction kunye nenkqubo yokucoca i-automobile exhaust. Xa i-γ- i-Al2O3 isetyenziswa njengomthwali, ngaphandle kwayo ingaba nemiphumo yokusabalalisa kunye nokuzinzisa amacandelo asebenzayo, inokubonelela ngeziko le-asidi yealkali esebenzayo, i-synergistic reaction kunye ne-catalytic active components. Ubume bepore kunye neepropathi zomphezulu we-catalyst zixhomekeke kwi-γ-Al2O3 carrier, ngoko ke umthwali wokusebenza okuphezulu unokufunyanwa kwimpendulo ethile ye-catalytic ngokulawula iipropathi ze-gamma alumina carrier.I-alumina esebenzayo ye-gamma yenziwa ngokubanzi nge-precursor yayo ye-pseudo-boehmite nge-400 ~ 600 ℃ yokuphelelwa ngubushushu obuphezulu, ngoko ke iipropati ze-physicochemical zomhlaba zimiselwa ubukhulu becala yi-precursor yayo ye-pseudo-boehmite, kodwa kukho iindlela ezininzi zokwenza i-pseudo-boehmite, kunye nemithombo eyahlukeneyo ye-diversityudo ye-Al-boehmite ye-Al-Boehmite ye-Al-Boehmite. Noko ke, kwezo catalysts kunye neemfuno ezikhethekileyo ukuba alumina carrier, bathembele kuphela kulawulo precursor pseudo-boehmite kunzima ukufikelela, kufuneka kuthatyathwe prophase ukulungiselela kunye post processing ukudibanisa iindlela ukulungisa iipropati alumina ukuhlangabezana neemfuno ezahlukeneyo. Xa ubushushu bungaphezulu kwe-1000 ℃ esetyenziswayo, i-alumina yenzeka inguqu yesigaba esilandelayo: γ→δ→θ→α-Al2O3, phakathi kwabo γ、δ、θ yi-cubic yokupakisha esondeleyo, umahluko ulele kuphela kunikezelo lwe-ion ze-aluminium kwi-tetrahedral kunye ne-octahedral, ngoko ke olu tshintsho lwesigaba alubangeli ulwakhiwo oluninzi. Ii-ion zeoksijini kwisigaba se-alpha zi-hexagonal ukupakisha ngokusondeleyo, amasuntswana e-aluminiyam oxide kukudibana kwakhona, indawo ethile yomphezulu inqabile kakhulu.

Ugcino:lKuphephe ukufuma, kunqande ukuskrola, ukujula kunye nokothuka okubukhali ngexesha lokuhamba, izibonelelo zemvula kufuneka zilungiswe.l Kufuneka igcinwe kwindawo eyomileyo nengena umoya ukunqanda ukosuleleka okanye ukufuma.Iphakheji:Uhlobo

Ibhegi yeplastikhi

Igubu

Igubu

Super isaka / Jumbo bag

Bead

25kg/55lb

25kg/55lb

150 kg/ 330 lb

750kg/1650lb

900kg/1980lb

1000kg/2200 lb

-

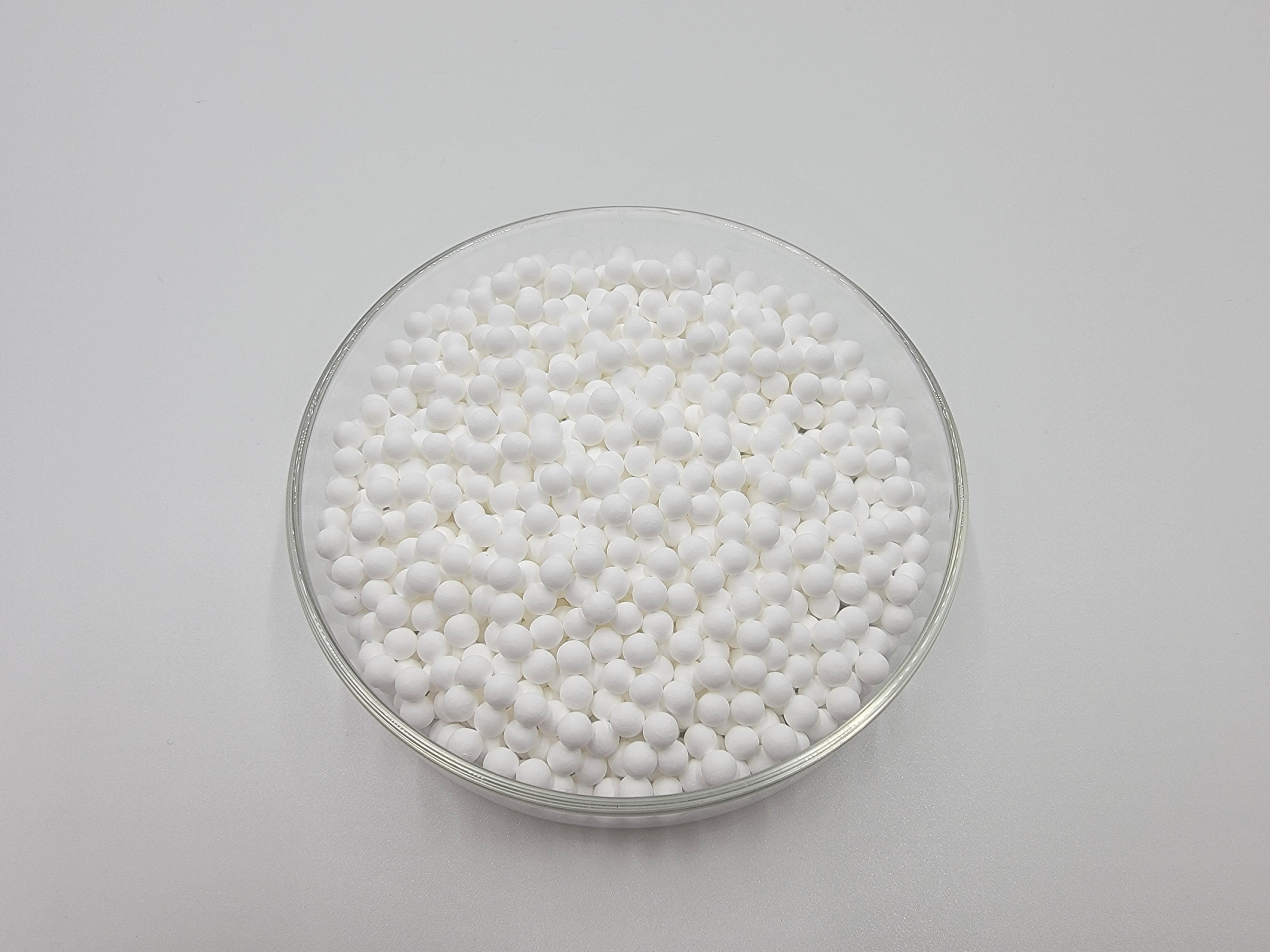

Ijeli ye-alumina emile okwespherical/Ibhola ye-alumina esebenzayo/ibhola ye-alpha ye-alumina

Ijeli yeAlumina eMilo eSpherical esebenzayo

yokutofa kwi-Air dryerUbuninzi bobuninzi (g/1):690Ubungakanani beMesh: 98% 3-5mm (kubandakanya 3-4mm 64% kunye 4-5mm 34%)Ubushushu bokuhlaziya sicebisa ukuba buphakathi kwe-150 kunye ne-200℃Umthamo we-Euiqlibrium womphunga wamanzi yi-21%Umgangatho woVavanyo

HG/T3927-2007

Into yovavanyo

Umgangatho /SPEC

Iziphumo zovavanyo

Uhlobo

Amaso

Amaso

Al2O3(%)

≥92

92.1

LOI(%)

≤8.0

7.1

Unizi lolwapho kuyiwa khona(g/cm3)

≥0.68

0.69

BET(m2/g)

≥380

410

Umthamo wePore(cm3/g)

≥0.40

0.41

Amandla Okutyumza(N/G)

≥130

136

Amanzi adsorption(%)

≥50

53.0

Ilahleko kwi-Attrition(%)

≤0.5

0.1

Ubungakanani obufanelekileyo(%)

≥90

95.0

-

Inkxaso ye-alpha alumina catalyst

I-α-Al2O3 yinto ene-porous, ehlala isetyenziselwa ukuxhasa i-catalysts, i-adsorbents, izinto zokuhlukana kwesigaba segesi, njl njl. I-α-Al2O3 yinqanaba elizinzile kunazo zonke ze-alumina kwaye ngokuqhelekileyo isetyenziselwa ukuxhasa amacandelo asebenzayo e-catalyst kunye nomlinganiselo ophezulu womsebenzi. Ubungakanani bepore ye-α-Al2O3 ye-catalyst carrier inkulu kakhulu kunendlela ye-molecular free, kwaye ukuhanjiswa kufana, ngoko ke ingxaki yokusasazwa kwangaphakathi ebangelwa ubungakanani obuncinci be-pore kwi-catalytic reaction system inokupheliswa ngcono, kunye neempendulo zecala le-oxidation enzulu zinokuncitshiswa kwinkqubo ngenjongo yokukhetha i-oxidation. Ngokomzekelo, i-catalyst yesilivere esetyenziselwa i-ethylene oxidation kwi-ethylene oxide isebenzisa i-α-Al2O3 njengomthwali. Ihlala isetyenziswa kwi-catalytic reactions kunye nobushushu obuphezulu kunye nolawulo lokusasazwa kwangaphandle.

Idatha yeMveliso

Indawo ethile 4-10 m²/g Umthamo wePore 0.02-0.05 g/cm³ Ubume I-Spherical, cylindrical, i-rascated ring, njl UAlfa hlambulula ≥99% Na2O3 ≤0.05% SiO2 ≤0.01% Fe2O3 ≤0.01% Imveliso ingenziwa ngokwezifiso ngokweemfuno zesalathisi -

I-Sulfur Recovery Catalyst AG-300

I-LS-300 luhlobo lwe-sulfur recovery catalyst enendawo enkulu ethile kunye nomsebenzi ophezulu weClaus. Imisebenzi yayo ime kwinqanaba eliphezulu lamazwe ngamazwe.

-

I-TiO2 Esekwe kwi-Sulfur Recovery Catalyst LS-901

I-LS-901 luhlobo olutsha lwe-TiO2 esekelwe kwi-catalyst enezongezo ezikhethekileyo zokubuyisela isulfure. Imisebenzi yayo ebanzi kunye nezalathisi zobugcisa zifikelele kwinqanaba eliphezulu lehlabathi, kwaye ikwindawo ephambili kushishino lwasekhaya.

-

I-AG-MS Spherical Alumina Carrier

Le mveliso yibhola emhlophe yebhola, i-non-toxic, i-tasteless, i-insoluble emanzini kunye ne-ethanol. Iimveliso ze-AG-MS zinamandla amakhulu, izinga lokunxiba eliphantsi, ubungakanani obuhlengahlengiswayo, umthamo wepore, indawo ethile yendawo, ubuninzi bobuninzi kunye nezinye iimpawu, zinokulungelelaniswa ngokweemfuno zazo zonke izibonakaliso, ezisetyenziswa ngokubanzi kwi-adsorbent, i-hydrodesulfurization catalyst carrier, i-hydrogenation denitrification catalyst carrier, i-CO sulfur resistant carrier transformation and field cataly cataly.